Food Dehydration Technology

Dehydration is one of the safest and most effective methods of food preservation. It involves the controlled removal of water naturally present in food, inhibiting the development of bacteria, mold, and other microorganisms, without the need for chemical preservatives.

Dehydrated foods are widely used in everyday life, often without notice. Many commonly consumed ingredients undergo partial or full dehydration to extend shelf life while maintaining safety and quality.

Food dehydration (for solid or liquid products) is a controlled process in which water or other liquids are removed through thermal vaporization below boiling temperature, using an unsaturated gaseous phase. This process is conducted under carefully regulated conditions of temperature, humidity, and airflow.

Air-based dehydration is the most commonly applied method. Heated air transfers energy to the food, causing moisture evaporation, while the airflow removes water vapor from the product surface.

Dehydration is considered one of the least aggressive preservation techniques. It preserves the structural integrity of food and retains most of its nutritional value. In vegetables used for powdered soups, for example, nearly all vitamins—particularly vitamin A—and essential minerals such as selenium, potassium, and magnesium are preserved.

This method is especially suitable for heat-sensitive components such as lactic acid bacteria.

Key Advantages of Dehydrated Foods

- No refrigeration required, significantly reducing storage and transportation costs

- Substantial weight reduction (up to 90% water removal), enabling easier and cheaper logistics

- Long shelf life without preservatives

- Rapid rehydration due to porous food structure, allowing water to easily reintegrate into the molecular structure

- Reduced risk of microbial contamination

- Ideal for emergency feeding, humanitarian aid, and large-scale operations

Dehydrated and MRE meals require minimal preparation time and effort, making them suitable for feeding large populations efficiently, including three complete meals per day under time-constrained conditions.

Strategic Objectives

- Immediate response to hunger, poverty, and malnutrition

- Rapid support to populations affected by crises or natural disasters

- Guaranteed nutritional intake for vulnerable groups

- Improvement of overall nutritional status and metabolic health

- Reduction of nutrition-related chronic diseases

- Lower contamination risk through controlled food processing

- Optimized logistics and supply-chain efficiency

READY MEALS IN RETORT PACKAGES

Balanced, Complete, and Safe Nutrition

Ready-to-eat meals in retort packages are developed in collaboration with public health and nutrition scientists and are designed for long-term use. These meals comply with NATO standards and provide balanced energy and nutritional value required for daily human performance.

The retort packaging process uses autoclave sterilization, ensuring microbiological safety while preserving taste, texture, and nutritional quality for extended shelf life.

Each individual ration is divided into three meals per day:

Breakfast

Lunch

Dinner

Convenient and Safe Packaging

Meals are packed in multilayer laminated retort pouches made from high-quality polymeric materials.

This packaging:

- Preserves nutritional value and flavor

- Allows heating within 10–15 minutes using a flameless heater or alternative heat sources

- Eliminates oxidation and metal migration risks associated with traditional cans

- Retort-packaged meals maintain taste and quality even after reheating and are ideal for use in field conditions.

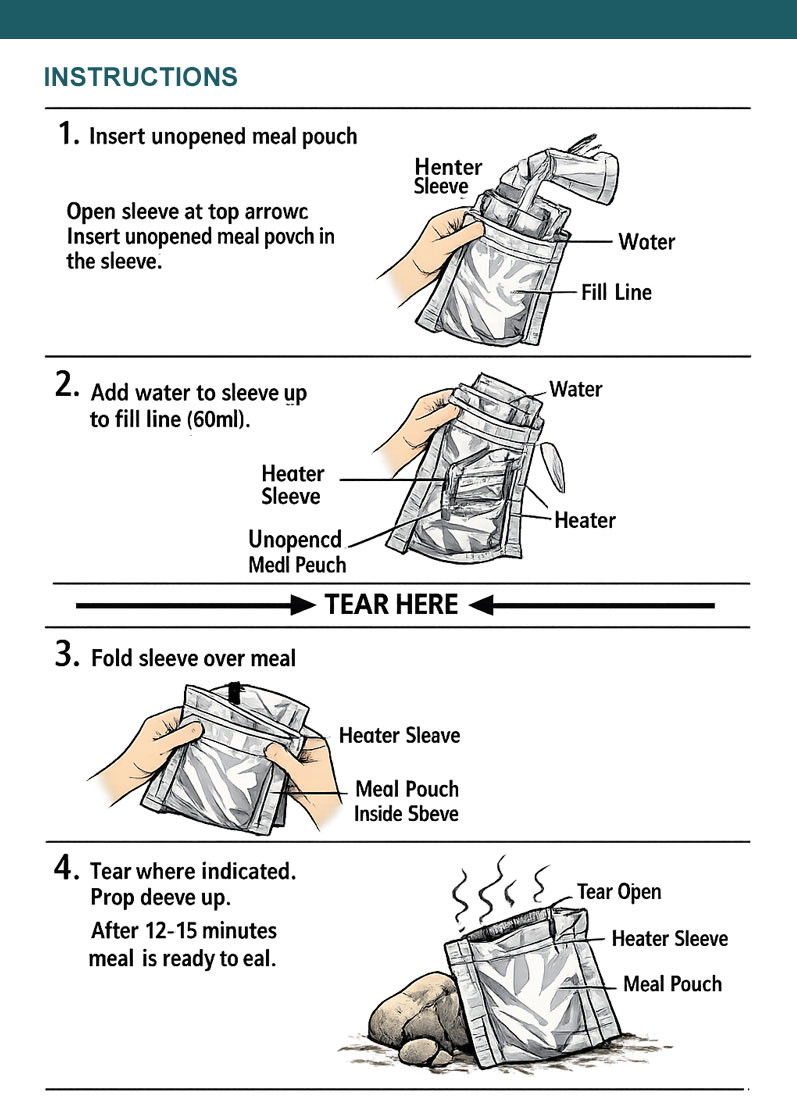

HOT FOOD – FAST AND CONVENIENT

Flameless Ration Heater Technology

A flameless ration heater is a self-contained heating system using a chemical reaction activated by water. When water is added, the reaction releases heat and steam, warming the meal to approximately +80°C.

Key Features

- Operates in all climatic conditions

- Requires only a small quantity water (drinking or non-potable water permitted)

- Hermetically sealed system ensures no contact between food and chemical elements

- Safe for indoor and outdoor use

- No flame, smoke, or odor produced

- Safety and Reliability

The flameless heater system is completely safe for human use. The chemical reaction is fully contained, produces no harmful emissions, and does not affect the food product in any way.

So, Dehydrated foods and retort-packaged ready meals provide a safe, efficient, nutritionally sound, and logistically optimized solution for humanitarian aid, disaster response, defense operations, and large-scale feeding programs.

Dehydration is one of the safest and most effective methods of food preservation. It involves the controlled removal of water naturally present in food, inhibiting the development of bacteria, mold, and other microorganisms, without the need for chemical preservatives.

Dehydrated foods are widely used in everyday life, often without notice. Many commonly consumed ingredients undergo partial or full dehydration to extend shelf life while maintaining safety and quality.

Food dehydration (for solid or liquid products) is a controlled process in which water or other liquids are removed through thermal vaporization below boiling temperature, using an unsaturated gaseous phase. This process is conducted under carefully regulated conditions of temperature, humidity, and airflow.

Air-based dehydration is the most commonly applied method. Heated air transfers energy to the food, causing moisture evaporation, while the airflow removes water vapor from the product surface.

Dehydration is considered one of the least aggressive preservation techniques. It preserves the structural integrity of food and retains most of its nutritional value. In vegetables used for powdered soups, for example, nearly all vitamins—particularly vitamin A—and essential minerals such as selenium, potassium, and magnesium are preserved.

This method is especially suitable for heat-sensitive components such as lactic acid bacteria.

Key Advantages of Dehydrated Foods

- No refrigeration required, significantly reducing storage and transportation costs

- Substantial weight reduction (up to 90% water removal), enabling easier and cheaper logistics

- Long shelf life without preservatives

- Rapid rehydration due to porous food structure, allowing water to easily reintegrate into the molecular structure

- Reduced risk of microbial contamination

- Ideal for emergency feeding, humanitarian aid, and large-scale operations

Dehydrated and MRE meals require minimal preparation time and effort, making them suitable for feeding large populations efficiently, including three complete meals per day under time-constrained conditions.

Strategic Objectives

- Immediate response to hunger, poverty, and malnutrition

- Rapid support to populations affected by crises or natural disasters

- Guaranteed nutritional intake for vulnerable groups

- Improvement of overall nutritional status and metabolic health

- Reduction of nutrition-related chronic diseases

- Lower contamination risk through controlled food processing

- Optimized logistics and supply-chain efficiency

READY MEALS IN RETORT PACKAGES

Balanced, Complete, and Safe Nutrition

Ready-to-eat meals in retort packages are developed in collaboration with public health and nutrition scientists and are designed for long-term use. These meals comply with NATO standards and provide balanced energy and nutritional value required for daily human performance.

The retort packaging process uses autoclave sterilization, ensuring microbiological safety while preserving taste, texture, and nutritional quality for extended shelf life.

Each individual ration is divided into three meals per day:

Breakfast

Lunch

Dinner

Convenient and Safe Packaging

Meals are packed in multilayer laminated retort pouches made from high-quality polymeric materials.

This packaging:

- Preserves nutritional value and flavor

- Allows heating within 10–15 minutes using a flameless heater or alternative heat sources

- Eliminates oxidation and metal migration risks associated with traditional cans

- Retort-packaged meals maintain taste and quality even after reheating and are ideal for use in field conditions.

HOT FOOD – FAST AND CONVENIENT

Flameless Ration Heater Technology

A flameless ration heater is a self-contained heating system using a chemical reaction activated by water. When water is added, the reaction releases heat and steam, warming the meal to approximately +80°C.

Key Features

- Operates in all climatic conditions

- Requires only a small quantity water (drinking or non-potable water permitted)

- Hermetically sealed system ensures no contact between food and chemical elements

- Safe for indoor and outdoor use

- No flame, smoke, or odor produced

- Safety and Reliability

The flameless heater system is completely safe for human use. The chemical reaction is fully contained, produces no harmful emissions, and does not affect the food product in any way.

So, Dehydrated foods and retort-packaged ready meals provide a safe, efficient, nutritionally sound, and logistically optimized solution for humanitarian aid, disaster response, defense operations, and large-scale feeding programs.

Vitamin and minerals (A, B1, B6, C, B4, Nlacin, Iron, Zinc), Glutene Free

We FEED People

REFUGEES

FAMILIES IN NEED

FOOD AID

FOR EMERGENCIES

FOR EMERGENCIES

WAR CONFLICTS

NATURAL

CATASTROPHES

CATASTROPHES

NGO's

SPECIAL

OCCASIONS

OCCASIONS

MIGRANTS

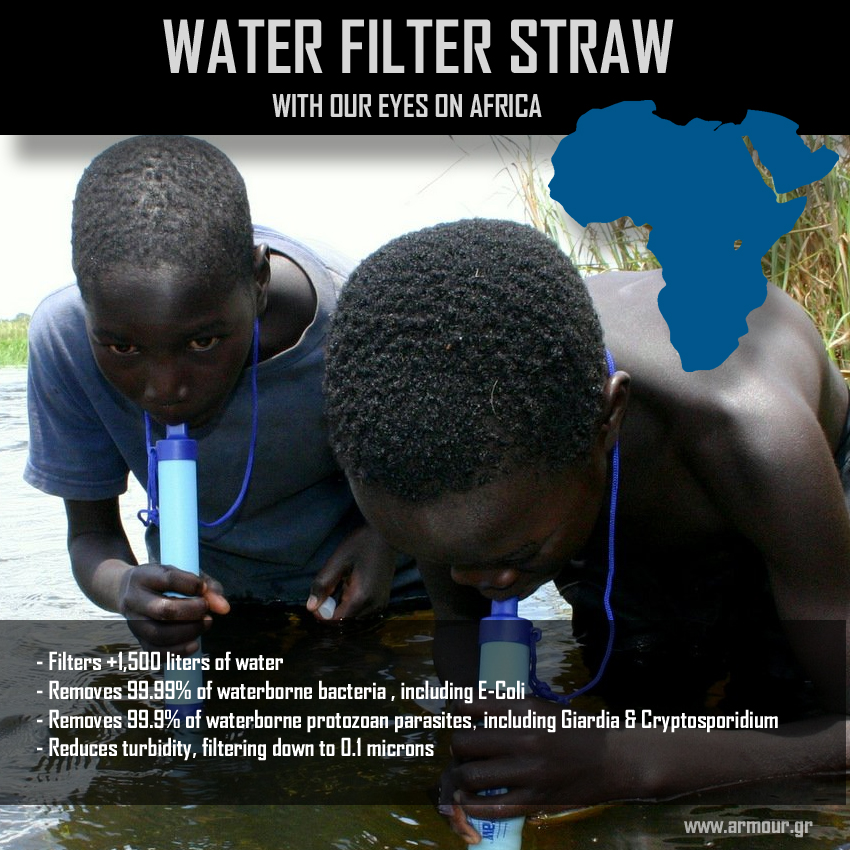

Water Filter Straw

MRE FLAMELESS RATIO HEATER BAG

Item : Heater bag

Material : Alu powder

Packing : heat pad with pp bag

Shelf life : 2 years

Customize package MOQ : 20,000pcs

Eg : 40g heat pad - heating 250-300gram food (cooked & seal )

Use step : Just need add water then you can enjoy hot food in next 12-15mins